Trooper performs spacing, tightening, and clustering operations.

100% electrical

- Silent

- Non polluting

100% autonomous

- Artificial intelligence

- Reactive and adaptative

- Working 24/24h ; all days

- Multi-batteries pack

Adapted to plant nurseries

- Robust and light

- Prevent floor damage

- Weather-proof

Innovative robot

- SIVAL of silver 2020

- Patented innovation

- Made in France

Reliable

- Constant working quality

- High reproducibility

Versatile (with extension)

- Pruning of vegetation

- Fertilizer applicator

- Insect trapping

Abilities

- Payload : until 30 kg

-

Up to 7 pots at a time (depending on the liter)

-

Max weight per pot : 10 kg

-

Output : 150~200 pots/hour (depends on liter)

- Liter max : 10L

- Diameter of the pots : 12 cm to 29 cm

Specifications

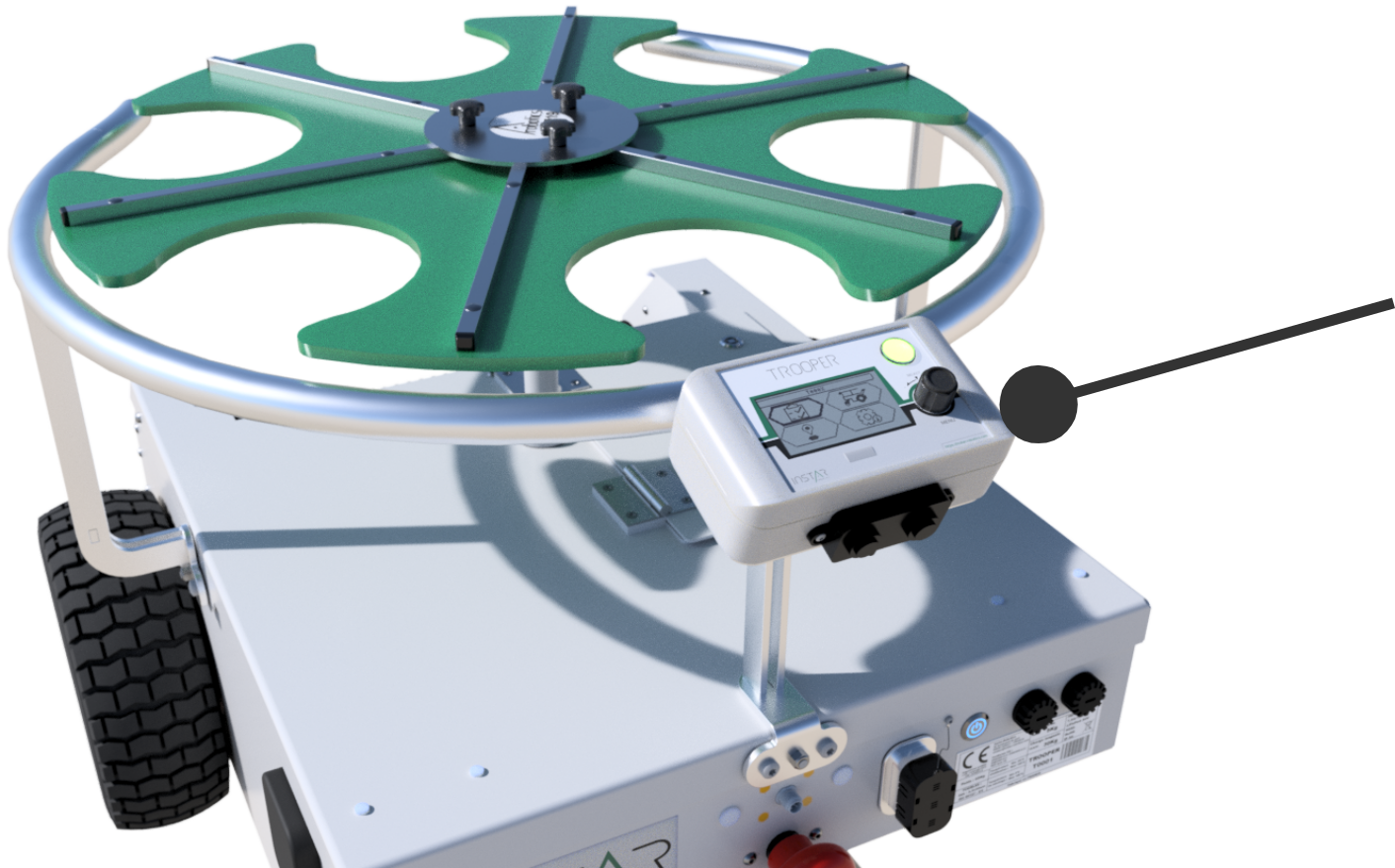

- Dimension : 70x60x65 cm

- Unloaded weight : ~65 kg

-

Works indoors and outdoors

- Protection : IP54

-

Resistant: rain, dust, sunshine

Autonomy

- 10 hours of battery life

- Full charge in 4 hours

- Working 7 days a week, 24 hours a day (even at night) with multi-batteries option

Mobility

- Maximum speed : 5km/h

-

Overcoming obstacles : 5cm

-

Maximum elevation: 5%

-

Working width: up to 12 meters

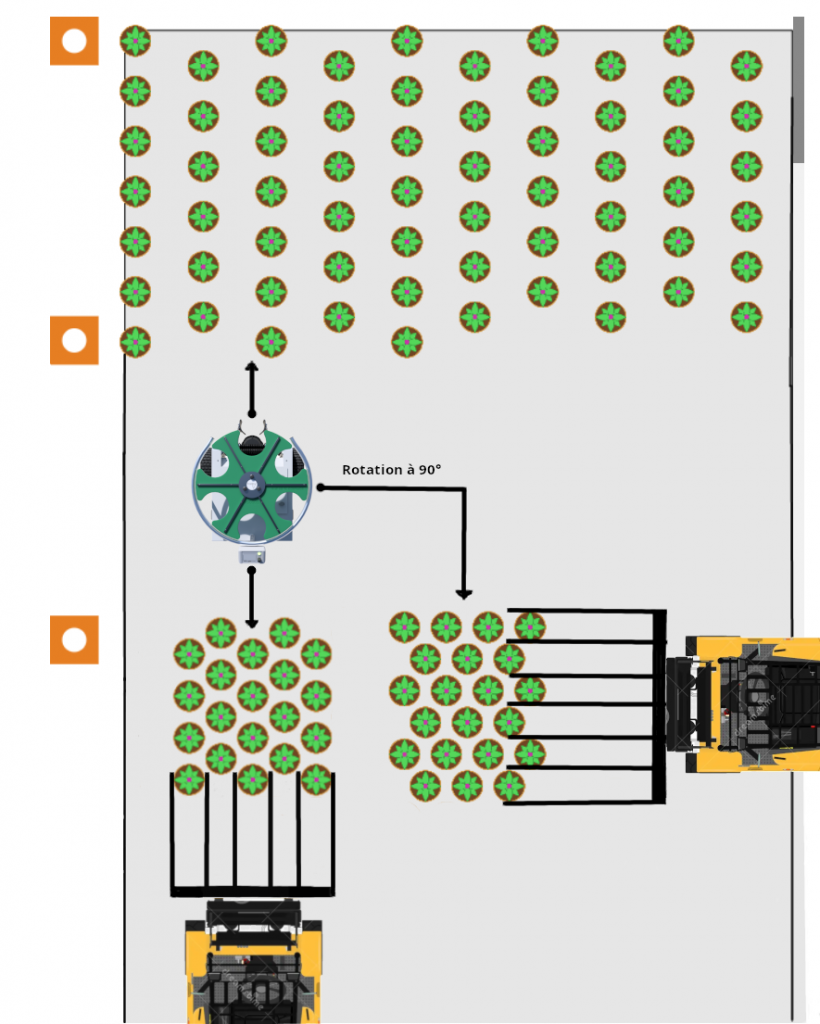

HOW IT WORKS

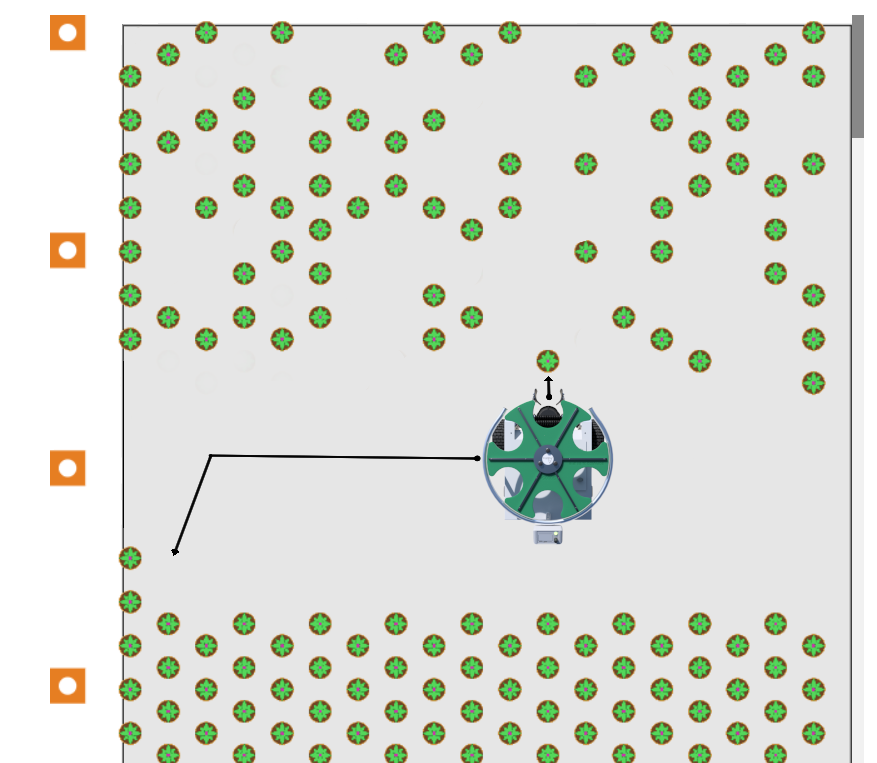

Spacing

1st step : Configure the task via an intuitive interface located at the back of the robot.

Simply select:

- The pot model

- Inter-pot spacing

- The size of the rows (number of pots per row)

2nd step : Prepare the production bed

(1) Mark off the production area by placing a line of plastic cones (1) on the ground with a spacing of approximately 2 meters

(2) Move the robot to the start of the line and use the interface to record the drop point (2)

(3) Move the robot to the location where the pots are dropped off and use the interface to register the grab point (3)

3rd step : An operator on a forklift collects the pots from the potting machine and then places them on the ground at the grab point (3).

4th step : The robot goes back and forth between the grab point (3) and the drop point (2) and performs the spacing in complete autonomy.

Finally : Go about your business. The robot alerts you when it’s finished.

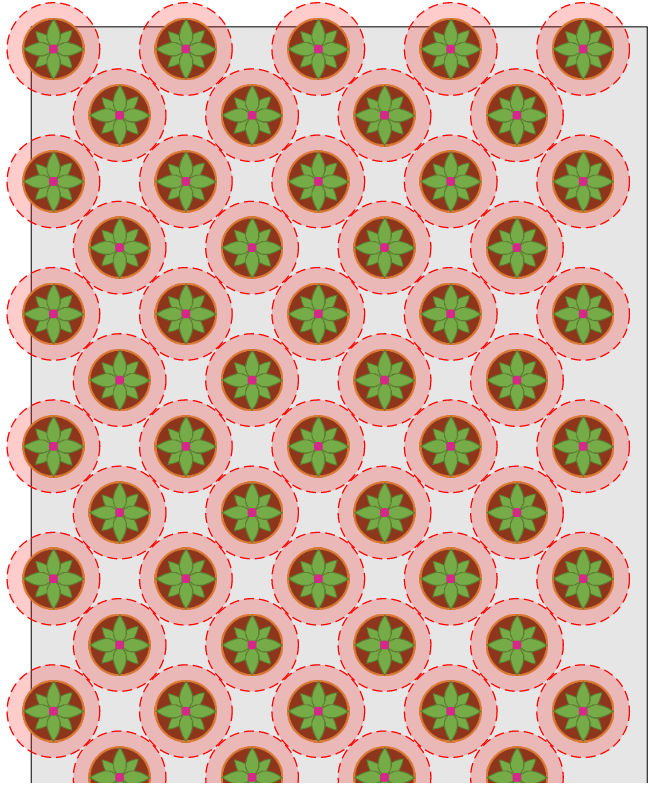

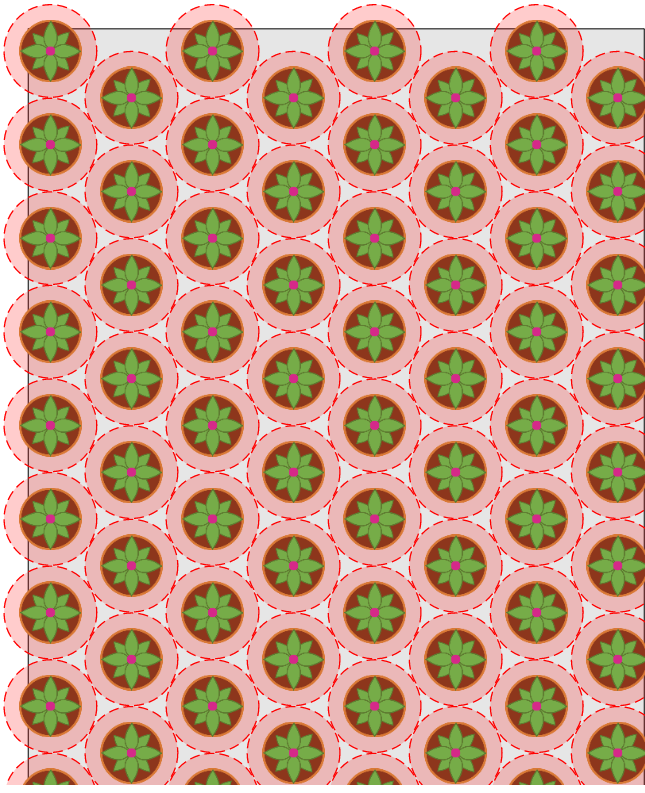

Optimize pot density per hectare by up to 15% thanks to its perfect quincunx spacing!

Classic manual spacing

Robot-optimized spacing.

Tightening

Close the spacing between rows to streamline your logistical operations

Advantages :

- Picking up stacks of pots with a fork

- Moving to other rows for new spacing as your plants grow

- Moving to the greenhouse for wintering

- Streamlines logistics for order preparation

Choice of pot stack orientation (straight or 90°) for removal based on access to your row

Clustering

Group your pots to optimize the occupancy rate of your rows

Advantages :

- Save space on your rows for new spacing arrangements

- Water savings during irrigation

- Free access for row maintenance

- Reducing travel distances during order picking

Profitability : Reduce your expenses.

Reduced pain : Lower the risk of MSD* and preserve your employees

* Musculo-skeletal disorder.

Serenity : Forget the stress of recruiting seasonal workers

Predictability : Secure your schedule

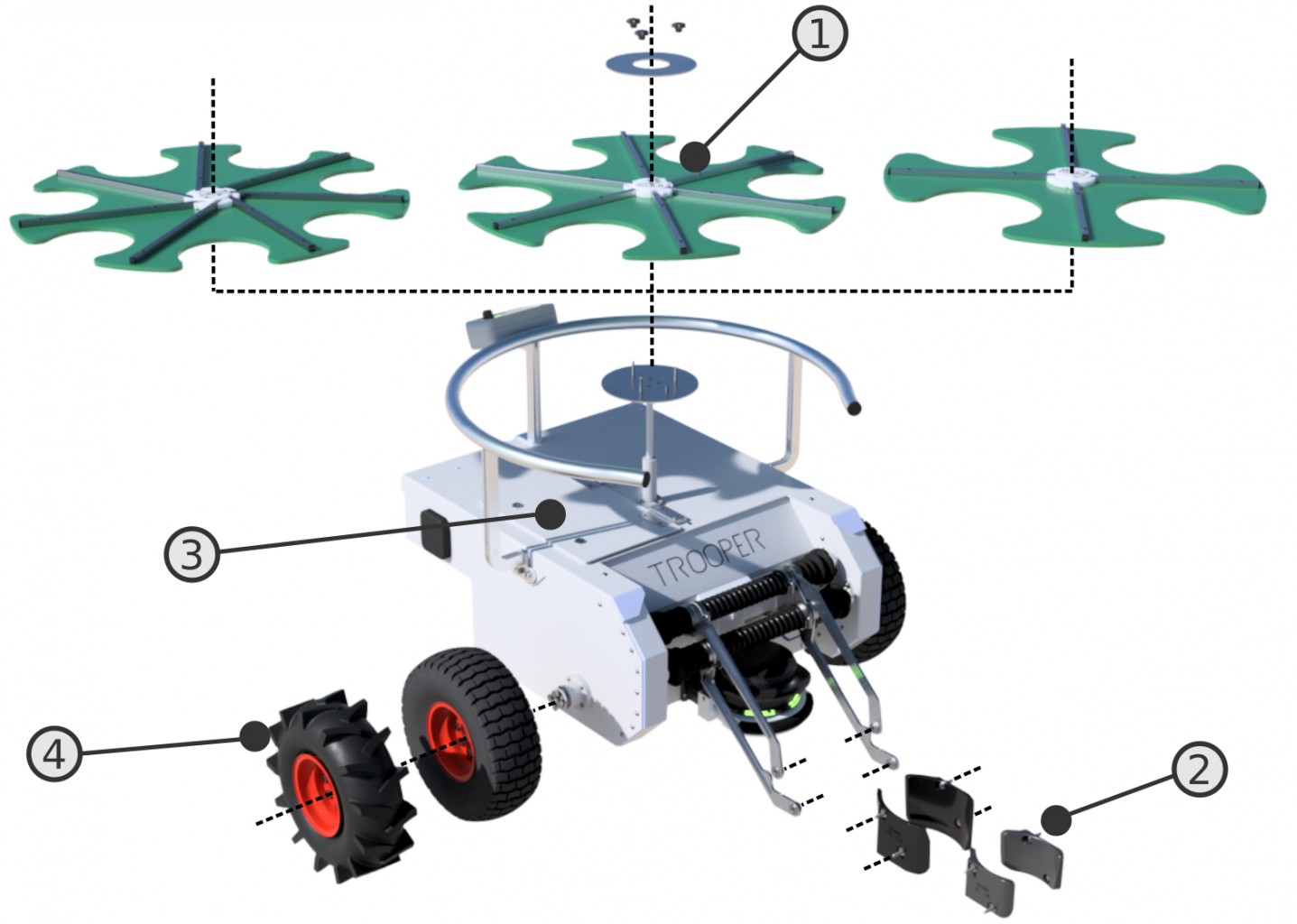

OPTIONS

Charger

-

Quick and intuitive change

-

Charger adapted to each capacity and each container shape

Hands

-

Quick and intuitive change

-

Small, medium and large liter hands

-

Hands adapted to each capacity and each container shape

“Easy Swap” battery

-

Optional second battery pack

-

Quick and easy replacement

Drive wheels

- Suitable for horticulture.

- Agricultural wheels: suited to rough terrain

- Smooth wheels: preserve the tarps on the ground